As manufacturing organizations reassess their technology landscape, many begin evaluating whether existing systems can continue to support evolving operational requirements.

Increased production complexity, supply chain volatility, and the need for more timely decision-making are prompting manufacturers to look more closely at integrated platforms that improve visibility and coordination.

In this context, cloud ERP solutions are often reviewed not simply as a deployment alternative, but as part of a broader effort to modernize how operational, planning, and financial data is managed.

Below are 9 advantages manufacturers commonly identify when evaluating cloud ERP as part of their overall systems strategy.

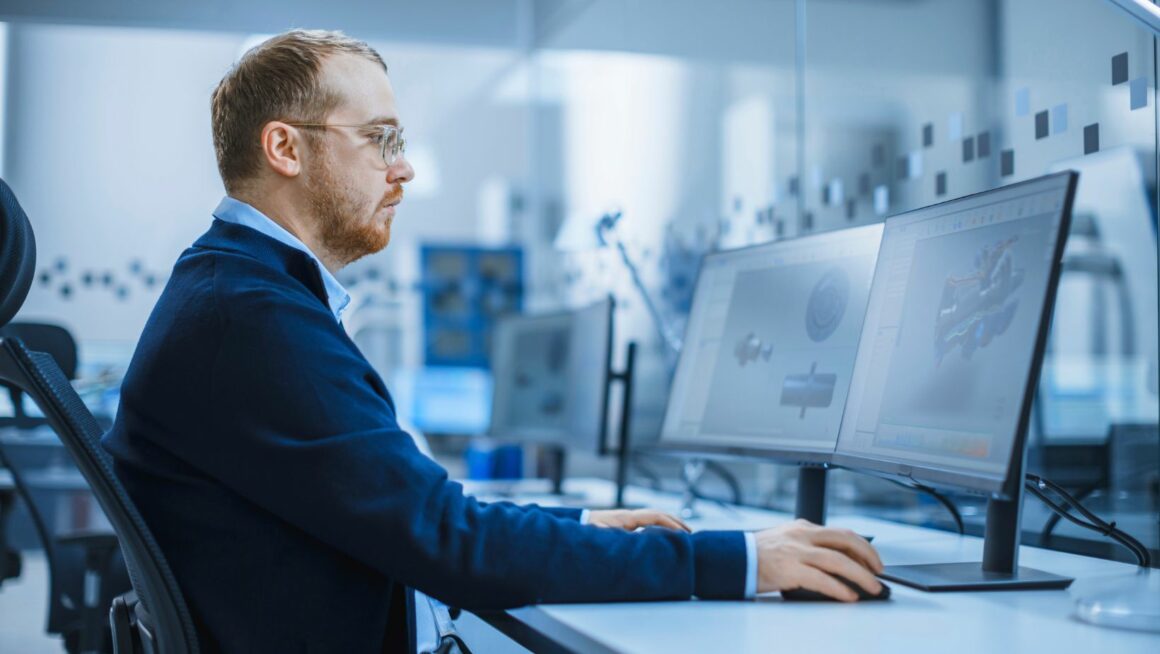

1. Centralized Access to Operational Data

One of the most immediate advantages manufacturers associate with cloud ERP is centralized data access. Production, inventory, purchasing, and financial information is maintained within a single system rather than spread across disconnected tools.

This centralized approach allows teams to:

- Work with consistent, up-to-date data

- Reduce manual data reconciliation

- Improve coordination across departments

When evaluated as part of a broader manufacturing software system, centralized data access supports more informed operational and planning decisions.

2. Improved Visibility Across Manufacturing Processes

Limited visibility is a common challenge in manufacturing environments that rely on siloed systems. Cloud ERP platforms are often assessed for their ability to provide real-time insight into production status, material availability, and order progress.

Manufacturers gain improved visibility into:

- Work-in-progress and production schedules

- Inventory levels and material consumption

- Order fulfillment and delivery timelines

This transparency helps teams identify issues earlier and respond more effectively to operational changes.

3. Greater Flexibility for Multi-Location Operations

Manufacturers operating multiple plants or warehouses often struggle with inconsistent processes and fragmented reporting. The cloud erp solutions are frequently evaluated for their ability to support distributed operations while maintaining centralized control.

Advantages in this area include:

- Standardized processes across locations

- Consolidated reporting for leadership teams

- Easier coordination between sites

This flexibility is particularly relevant for manufacturers planning expansion or managing geographically dispersed operations.

4. Reduced Dependence on Internal IT Infrastructure

Traditional on-premise systems often require significant internal resources to manage servers, upgrades, and system availability. Cloud ERP shifts much of this responsibility to the provider.

From an evaluation standpoint, manufacturers often consider:

- Reduced hardware and maintenance requirements

- More predictable system updates

- Improved system reliability

While IT oversight remains important, cloud deployment can simplify long-term system management compared to legacy environments.

5. Better Alignment Between Production and Inventory

Production efficiency depends heavily on accurate inventory data. When inventory systems are disconnected from production planning, manufacturers may encounter material shortages or excess stock.

Cloud ERP platforms help improve alignment by:

- Linking inventory availability directly to production schedules

- Tracking material usage in real time

- Supporting more accurate demand planning

This integration reduces last-minute disruptions and supports more reliable production execution.

6. Stronger Integration of Financial and Operational Data

Manufacturers often evaluate ERP systems based on how well they connect operational activity with financial reporting. Cloud ERP platforms are commonly assessed for their ability to improve this alignment.

Benefits in this area include:

- More accurate job costing

- Improved margin visibility

- Better financial forecasting based on operational data

When compared with fragmented systems, this integration supports more consistent and transparent financial analysis.

7. Improved Scalability as Business Needs Change

As manufacturers grow or adjust their business models, system scalability becomes increasingly important. Cloud ERP solutions are often considered because they can adapt to changing requirements without significant infrastructure investment.

Scalability advantages typically include:

- Easier addition of users or locations

- Support for increasing transaction volumes

- Modular functionality that evolves with business needs

This makes cloud ERP particularly relevant for manufacturers planning phased growth.

8. Enhanced Collaboration Across Departments

Effective collaboration depends on shared access to accurate information. Cloud ERP environments enable teams across production, purchasing, finance, and management to work from the same data set.

This supports:

- Faster cross-functional decision-making

- Reduced miscommunication between departments

- More consistent execution of business processes

For manufacturers comparing cloud-based systems with traditional deployments, improved collaboration is often a meaningful differentiator.

9. Support for Long-Term Systems Strategy

Rather than addressing isolated challenges, many manufacturers evaluate cloud ERP as part of a longer-term systems roadmap. The ability to support future process improvements, reporting needs, and operational changes is often a key consideration.

When reviewed alongside existing manufacturing erp environments, cloud-based platforms are frequently seen as a way to modernize systems incrementally while maintaining operational continuity.

Final Consideration

The advantages manufacturers gain from cloud ERP extend beyond technology deployment. By improving visibility, integration, and scalability, cloud ERP solutions support more coordinated operations and better-informed decision-making.

For manufacturers in the evaluation stage, understanding how these advantages align with current challenges and long-term goals is an essential step in determining whether cloud ERP is the right strategic fit.