Choosing the right components for your Printed Circuit Board (PCB) can feel like navigating a maze. With countless options, how do you ensure you’ve selected the best for your project? I’m here to simplify this complex process, offering nine crucial tips to guide your decision-making.

Whether you’re a seasoned engineer or a beginner in electronics, these tips will equip you with the knowledge to make informed choices. From understanding component specifications to considering cost-effectiveness, we’ll delve into the key aspects that can make or break your PCB design. So, let’s embark on this journey to master the art of choosing PCB components.

Understanding PCB Components

Grasping the pivotal role of PCB components helps simplify the intricate process of PCB assembly. Let’s decipher their fundamental roles in circuit design and learn about some common types of PCB components.

The Role of PCB Components in Circuit Design

PCB components act as the building blocks in circuit design. These parts collectively serve a sole purpose – to control the flow of electricity through the intricate network, achieving the desired electronic function. For instance, in designing a PCB, the first thing to do is attach the PCB components. Without these parts, the PCB board remains a mere non-functional piece of material.

Common Types of PCB Components

PCB consists of a multitude of components, each distinctive in its kind and role. A complete BOM can help PCB designers discern which components are required for the design. Some common types:

- Resistors: They limit the flow of electric current through the circuit.

- Capacitors: These store and discharge energy when deemed necessary.

- Diodes: Diodes, like one-way traffic signs, only allow current to flow in one direction.

- Transistors: Essentially an electric switch, it’s used to amplify or switch electronic signals.

By identifying the role and function of these components, the task of choosing appropriate elements during PCB assembly becomes more precise and effective. Remember, the right component selection makes your PCB design successful; contact your PCB supplier for additional help, if needed.

Key Factors in Choosing PCB Components

When it comes to designing PCB components, several decisive factors complicate the selection process. I’ve listed nine key areas to take into account when streamlining your PCB assembly process and selecting PCB components:

- Consider the Full Functionality Milestone: Bear in mind that the cumulative effect of all your chosen components creates the complete functionality of your device. For instance, if you’re creating an amplifier, the transistors, resistors, and capacitors you select determine the quality and volume of output.

- Evaluate Environment Compatibility: Gauge how your PCB components will fare in construction. For example, if the PCB operates inside a hot, humid environment, pick components that are resistant to these conditions.

- Weigh Cost Significance: Factor in the cost of components. Typically, more durable, high-performing parts come at a higher price. Balancing cost and performance proves essential in the purchasing decision.

- Analyze Availability and Lead Time: Some components have extended delivery periods, which could delay your project. Choosing readily available parts from reliable suppliers can streamline the assembly process.

- Understand Specification Synchronization: Ensure that chosen components meet the technical specifications of the PCB design. For instance, it’s essential to match impedance standards.

- Contemplate Component Size: This plays a pivotal role in compact designs. Smaller components minimize the overall footprint, but could be more challenging to work with during installation.

- Investigate Manufacture Longevity: Check the producer’s track record. Manufacturers who’ve been in the business for a while likely offer more reliable components.

- Examine Component Compatibility: Make sure that all components work well with one another. For instance, if the resistors can’t handle the current from the power source, they could adversely affect the circuit’s functionality.

- Prepare a Complete BOM (Bill of Materials): Providing a complete BOM can help PCB suppliers understand your needs. It allows them to spot potential challenges and propose suitable solutions.

Certain tasks, like attaching the PCB, demand extra consideration. Always contact your PCB supplier if you need clarification or additional assistance. They often provide valuable insights that are instrumental in choosing appropriate components for your design. Remember, careful deliberation during component selection can mean the difference between a successful and a troubled PCB assembly.

Tip 1: Consider the Functionality Needed

Diving deep into the first tip of component selection, the functionality of every part analyzes. It’s paramount to align the capacities of each component with the expected circuit goals.

The functioning of various elements is instrumental in deciding how your PCB operates.

How Different Components Serve Different Functions

Each component in a PCB assembly, from the most mundane to the highly specialized, serves a distinct function. For example, resistors control current flow, capacitors store and release electrical energy, and transistors function as amplifiers or switches. My approach to designing PCB takes this into account so that I may build an efficient and effective circuit.

Aligning Component Functionality with Circuit Goals

Aligning your component functionality with circuit goals is a crucial aspect of PCB design. I use resistors, capacitors, and transistors, among other components, to ensure that the circuit performs its desired tasks.

The thing to do is attach the PCB elements in a way that they work cohesively.

Acomplete BOM can help PCB designers achieve this. For instance, if a circuit aims to amplify audio signals, we select components that enhance signal strength without distortion. By doing this, one can ensure efficiency and longevity of the PCB assembly. It becomes easier to follow through with the component selection as one understands more about the component’s role in the overall functionality.

Remember, it’s more than just choosing components; it’s about understanding their roles and how they contribute to the entire circuit’s performance. A well-planned process can dramatically improve the reliability and performance of your board. Designing PCB components isn’t simple, but it’s worthwhile for a smooth and efficient PCB assembly.

Tip 2: Assess the Quality of the Components

Consistent with selecting appropriate components for a PCB, it’s vital to dive into the subtleties of component quality. High quality ensures efficient PCB assembly, extending the durability and functionality of the entire unit.

The Importance of Quality in PCB Components

Quality components offer a bedrock for successful PCB design and assembly. They mitigate potential performance issues, decrease repair costs, and enhance product longevity as I’ve realized in my projects. They align with the specification of the circuit, ultimately contributing to its optimal performance.

Additionally, top-notch quality ensures the components are compatible with the environmental conditions they’ll be exposed to, ensuring the robustness of the PCB assembly. A complete BOM can guide the selection process, serving as a barometer for the required component quality.

Identifying High-Quality PCB Components

Spotting high-quality components is crucial in crafting an efficient PCB assembly. Renowned manufacturers generally provide such products; their reputation often hinges on delivering top-tier hardware.

They offer comprehensive datasheets detailing component specifications, tolerances, and stress ratings, making them a reliable source for high-quality components.

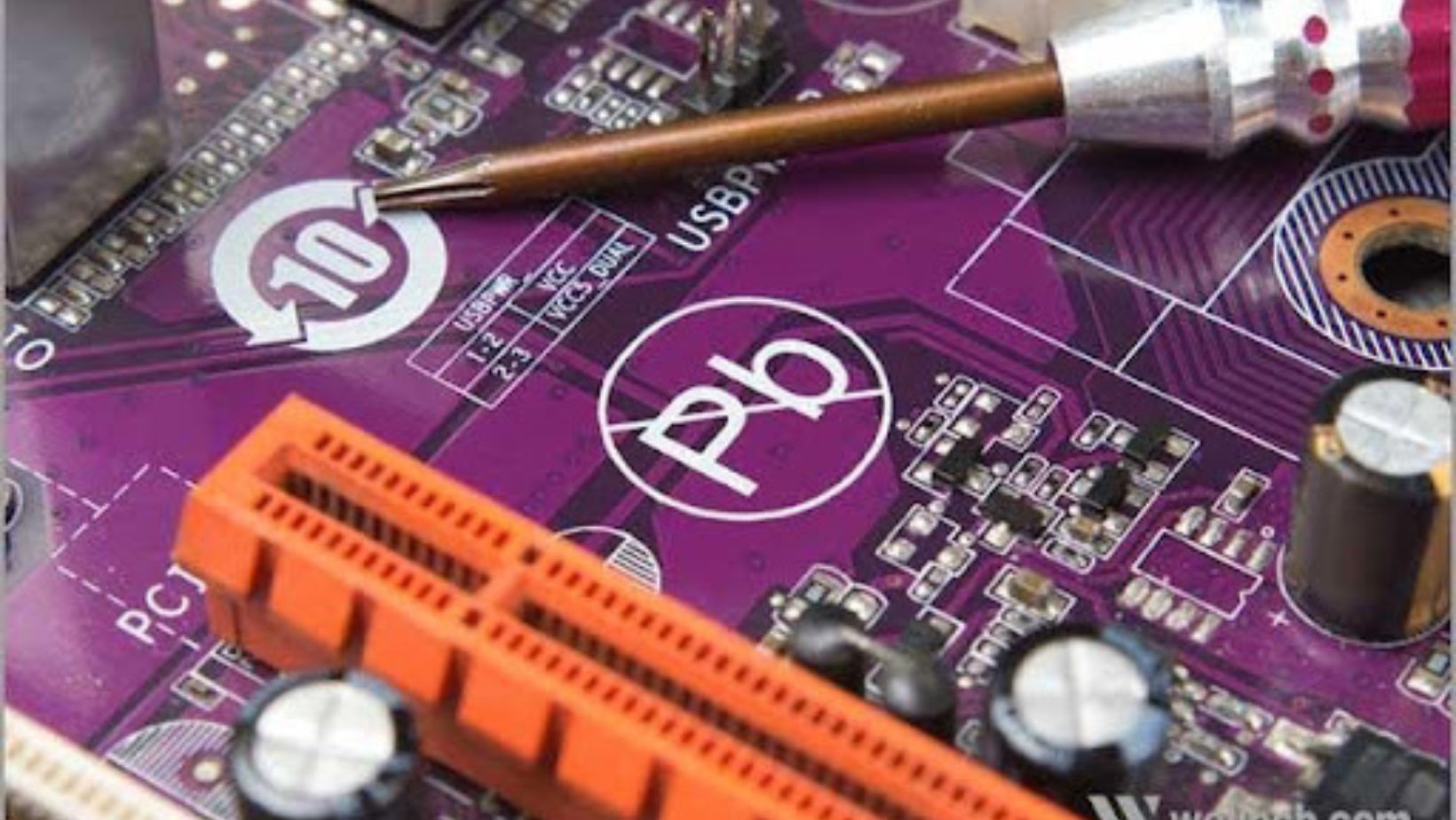

Signs of a quality component include precise dimensions, uniform finishes, and appropriate markings. The first thing to do after procuring the components is to visually inspect them for these qualities. Furthermore, it’s essential to test functionality before attaching them to the PCB. A faulty component, regardless of its perceived quality, can disrupt your PCB’s functioning. Thus, take the time to verify component quality before the assembly process.

Conclusion

Choosing the right PCB components isn’t just a box to check off; it’s a crucial step in the design and assembly process. It’s all about understanding the specs, aligning functionality with your circuit’s objectives, and ensuring quality. Always remember that each component serves a distinct purpose, and the right choice can significantly enhance your PCB’s efficiency and longevity.

Don’t underestimate the power of a comprehensive BOM, either. It’s your roadmap to successful assembly. And when it comes to quality, it’s worth every penny. High-quality components reduce performance issues and repair costs while extending the life of your product. So, keep your eyes peeled for renowned manufacturers, detailed datasheets, and precise dimensions. It’s not just about assembling a PCB; it’s about building a PCB that lasts. And with these tips in mind, you’re well on your way to doing just that.